Lot 02, Thuy Van Industrial Zone, Thuy Van ward, Viettri city, Phutho province, Vietnam

+84966500694

Roll-bending or curving, designates the manufacture of sheet-metal parts that are rolled or curved into cylindrical shapes or shapes that have a smooth radius associated with them. We offer a first class sheet metal rolling service in Vietnam and to the world, with a system of curling machine that has potentials to curl sheet metal with the thickness up to 30mm

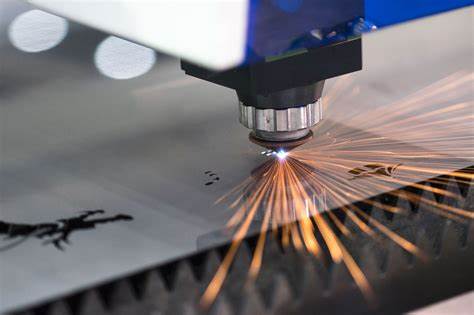

A powerful laser beam is used in laser cutting to cut through any material. Light Amplification by Stimulated Emission of Radiation, or laser. One of the most well-liked industrial cutting methods is this one. We are using a CNC laser cutting machine with 6kW of power to cut carbon steel up to 25mm thickness and 16mm with stainless steel.

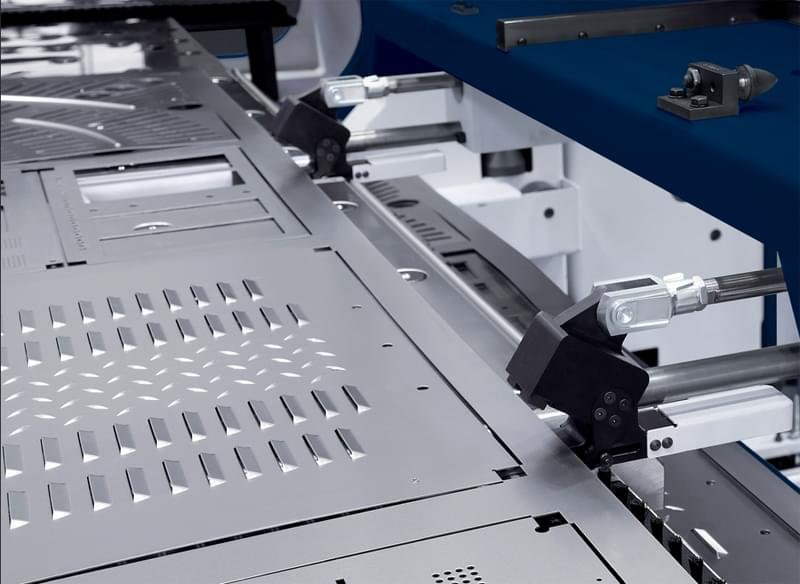

Bending is one of the most used sheet metal manufacturing processes. This method of angular material distortion is also referred to as press braking, flanging, die bending, folding, and edging. The relevant solutions will be provided by Tecvina depending on the clients' commodities.

By applying a enough shearing force, sheet metal punching is a cutting technique that removes material from a piece of sheet metal. A variety of hole and cut shapes and sizes can be made with CNC punching. The most common punched holes have a simple geometric shape (such as a circle, square, rectangle, etc.) or a mixture of those shapes.

Austenitic: Stainless steel (any of the 300 series steels) is a non-magnetic, chromium- and nickel-rich steel with minimal carbon content. Because of its formability and corrosion resistance, these stainless steel grades are the most popular. Ferritic: Non-heat-treatable, magnetic stainless steels containing 11 to 30 percent chromium and little or no nickel. Typically utilized in non-structural applications where high corrosion resistance is required, such as in marine applications, or where aesthetics take precedence. These elements are most frequently found in 400-class stainless steels. Martensitic: A group of chromium steels that typically do not contain nickel is used to generate corrosion-resistant and heat-treatable steel grades with a wide range of hardness and strength.

A process in which hot-rolled steel is treated to achieve a smoother surface and closer tolerances during forming. CRS alloys are available in the grades 1008 and 1018.

Metallic plate material galvanized in hot-dipped steel or galvanized steel and then galvanized again. Galvanization is the procedure of applying a protective zinc coating to steel to prevent corrosion and rusting. Annealing is a thermal process that alters the microstructure of a material, which typically reduces its hardness and increases its ductility for easier fabrication, in order to modify its mechanical or electrical properties.

Aluminum sheet metal is the material of choice for a variety of industrial applications due to its high strength-to-weight ratio and inherent resistance to corrosion. Grade 1100 has exceptional corrosion resistance, excellent functionality, and high thermal and electrical conductivity. Frequently found in the electrical grid and transmission cables. Due to its moderate strength and high workability, grade 3003 is a common alloy for general applications. Utilized for cookware and thermal transfers. Typical metal fabrication utilizes grades 5052 and 6061. Grade 5052 is the most commonly used, shapeless, malleable, and corrosion-resistant alloy among the stronger alloys. Grade 6061 is the most commonly employed solid structural alloy for extrusions or high strength components, such as vehicle and marine framework.

With a low zinc concentration, cold work, welding, and brazing can be performed with ease. A high copper concentration permits the formation of a protective oxide (patina) on the surface of a metal to prevent further corrosion. This patina gives architectural and non-architectural consumer goods an artistic appearance that is frequently very appealing.

ietnam’s advantage over China is its inexpensive labor force. While wages have increased in major Chinese cities and manufacturers are struggling to remain profitable, the cost of labor in Vietnam can be as low as one-third of China’s. In certain regions of Vietnam, the minimum wage can be as low as $125 per month. In light of this, wages in Vietnam are rising quicker than in China and, in some instances, are approaching parity. In recent years, Vietnam has been anticipated or viewed by some as the 2nd Factory of the world, or the next Manufacturing Hub of the world after China. Vietnam’s labor costs are still very attractive to investors, and the “golden population” structure is ideal for the growth of manufacturing industries.

With three sides confronting the sea, Vietnam is at the intersection of the marine and continental economies of Asia in general and Southeast Asia in particular due to its advantageous geographical location. In addition, Vietnam is situated on the Trans-Asian road route (as part of the United Nations Economic and Social Commission for Asia and the Pacific-led highway initiative). The Vietnamese government is constructing infrastructure for the freight transportation industry. Vietnam is a country with a long sea route, the domestic road system has been well-invested in recent years, and domestic transportation costs are at a reasonable level, contributing to a reduction in total logistics costs. As a result, foreign businesses will be able to construct and develop logistics supply chains in Vietnam with relative ease in order to interact with the region.

Along with Vietnam’s prospective geographic location, the country’s political stability is another factor that attracts investors. Vietnam lacks a political crisis, and its economic development policies are always consistent and secure.

As an end-to-end manufacturer, we optimize production costs by advancing the development of production automation, implementing new technologies, and continuously enhancing human productivity in accordance with 5S, Kaizen, and other methodologies. As a result, we can offer our customers products that are both more valuable and less expensive.

Controlling delivery time falls into two categories – production time and shipping time. When working with Tecvina, we commit to the production time through a contract in order to penalize the slow progress of goods, and we also have a good relationship with the transport units to ensure that the transportation time is shortened. Moreover, the export procedures are transparent and clear, so customers can have confidence in our services.

TECVINA builds a product quality control team according to each customer's requirements. Every year, our staff is sent for training to improve product quality control capacity. In addition, we also welcome customers to have a third party to control product quality

The issue of technology secrecy or intellectual property of the customer is committed in writing and complies with international law. Techvina's goal is always to maintain relationships with customers for many years and become their trusted partner.

Lot 02, Thuy Van industrial zone, Thuy Van ward, Viet Tri city, Phu Tho province, Vietnam

Hours: 7 AM to 5 PM, M-S. Closed Sunday.

Phone: +84-966-500-694

Email: tecvinamec@gmail.com