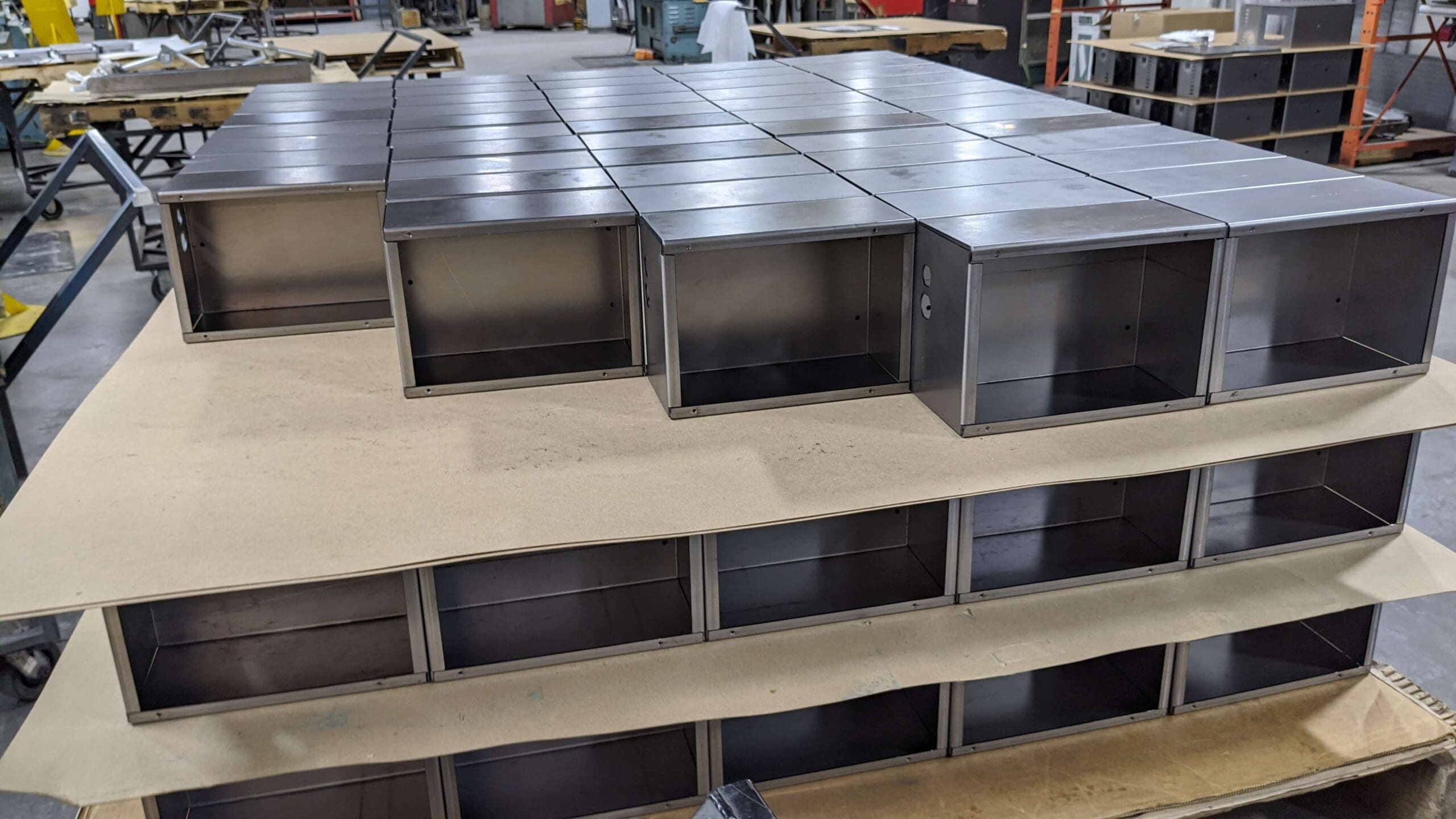

Sheet metal enclosures serve as protective coverings for electronic, automotive, aerospace, and telecommunication devices. They shield sensitive components from environmental factors such as dust, moisture, and electromagnetic interference.

What are Sheet Metal Enclosures?

Sheet metal enclosures are protective casings made from thin metal sheets, typically steel or aluminium. These enclosures are formed through cutting, bending, and assembling processes to create a robust structure.

Types of Sheet Metal Enclosures

Sheet metal enclosures come in various designs, including chassis enclosures, rack-mount enclosures, and junction box enclosures, each tailored to specific applications and equipment requirements.

Applications in Diverse Industries

Sheet metal enclosures find extensive use across multiple industries due to their versatility and durability.

Electronics

In the electronics industry, sheet metal enclosures house circuit boards, control panels, and other sensitive electronic components, safeguarding them from external damage and ensuring optimal performance.

Automotive

Automotive manufacturers utilize sheet metal enclosures for housing electrical systems, engine components, and onboard computers, enhancing vehicle reliability and safety.

Aerospace

In the aerospace sector, sheet metal enclosures are integral to aircraft avionics, providing protection against extreme temperatures, vibrations, and electromagnetic interference.

Telecommunications

Telecommunication equipment relies on sheet metal enclosures to house servers, routers, and communication devices, ensuring uninterrupted network connectivity and data transmission.

Manufacturing Process

The production of sheet metal enclosures involves several stages to ensure precision and quality.

Design

The design phase involves conceptualizing enclosure specifications, including dimensions, material selection, and component layout, to meet the client’s requirements.

Material Selection

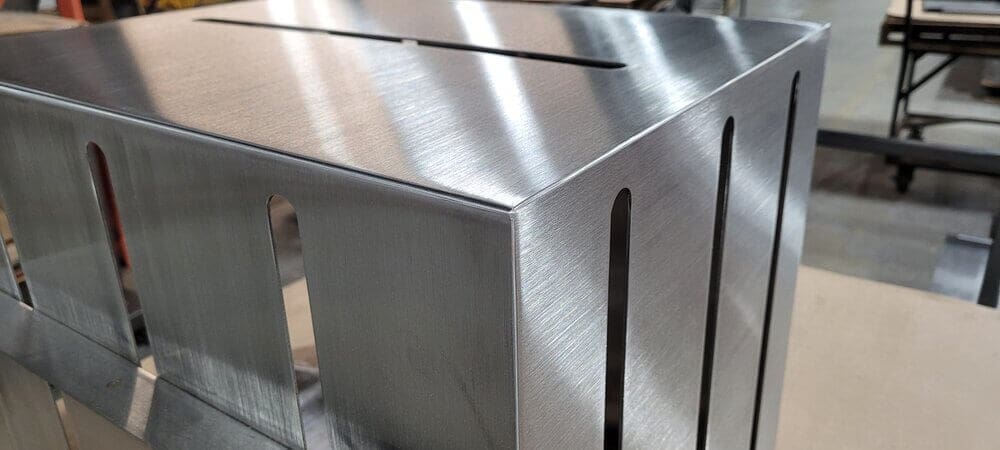

Choosing the appropriate metal sheet material is crucial to the enclosure’s performance, considering factors such as strength, conductivity, and corrosion resistance.

Cutting and Forming

Metal sheets are cut into the desired shapes using techniques like laser cutting or punching, followed by bending and forming processes to create the enclosure’s structure.

Joining

Components are assembled using welding, riveting, or fastening methods to ensure structural integrity and sealing against environmental elements.

Finishing

The final step involves surface treatment processes such as powder coating or painting to enhance durability, aesthetics, and corrosion resistance.

Tecvina: Quality Production

Tecvina is a renowned manufacturer of sheet metal enclosures, known for its commitment to excellence and customer satisfaction

Company Overview