Sheet metal punching and the differences

Metal punching is a process that uses a machine to force a tool, called a punch, through a sheet of metal to create a hole or a shape. Metal punching can be used for various materials, such as aluminum, stainless steel, copper, brass, and more. Metal punching can also perform other operations, such as embossing, […]

Everything You Need To Know About Powder Coating

Powder coating is a type of coating that is applied as a free-flowing, dry powder. It is electrostatically charged and then cured under heat or with ultraviolet light. It produces a hard finish that is tougher than conventional paint and can be used on metals, plastics, composites, and other materials Some of the advantages of […]

Do you know about MIG/MAG Welding

MIG/MAG welding, also known as gas metal arc welding, is a frequently used welding process that allows for high welding speeds. There are two different types of this process: ✓ Metal Inert Gas (MIG) welding: This process uses inert, or non-reactive, shielding gases such as argon, helium, or a mix of the two. The heat […]

IS ROBOTIC WELDING RIGHT FOR YOU?

Robot welding is the use of mechanized programmable tools, which completely automate a welding process by both performing the weld and handling the part. It’s commonly used for resistance spot welding and arc welding in high production applications, such as the automotive industry. The major components of arc welding robots are the manipulator or the […]

What is TIG Welding Services

TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), is a process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used, though some welds, known as autogenous […]

Do you know about spot welding?

Spot welding is a type of electric resistance welding that is used to join two or more metal sheets together. It works by applying pressure and heat from an electric current to a small spot where the metal surfaces contact. Spot welding is commonly used for welding low carbon steel, stainless steel, nickel alloys and […]

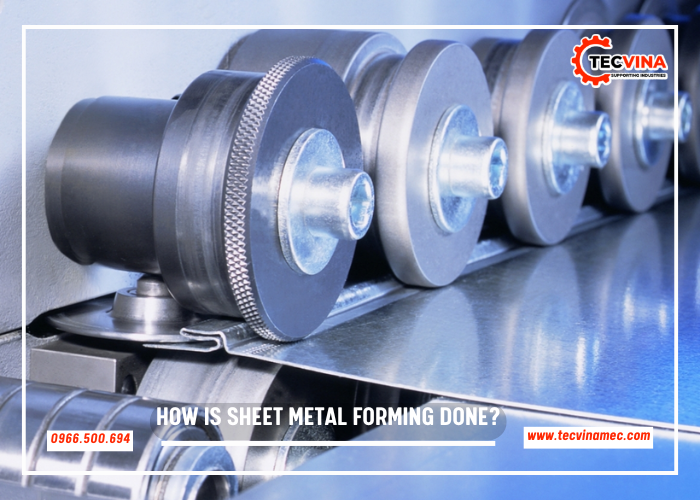

How Is Sheet Metal Forming Done?

Sheet metal forming is the process of shaping metal sheets into desired shapes by bending, cutting, punching, or other processes. This process plays an important role in many industries such as construction, automotive, aerospace, machinery, and furniture. What is Sheet Metal Forming? Sheet metal forming is a manufacturing process that involves shaping and bending sheet metal […]

Types of Fabrication Materials for Your Metal Part

Did you know that nearly 75% of all the elements on the periodic table are classified as metals? This vast array of options provides a diverse selection of fabrication materials for creating metal parts through cutting, welding, machining, forming, or assembling processes. While virtually any metal or metal alloy can be utilized in the fabrication […]

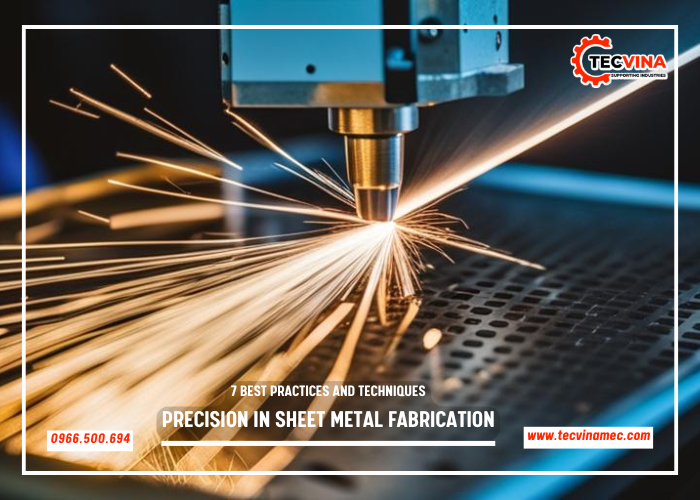

7 Best Practices and Techniques for Achieving High Precision in Sheet Metal Fabrication

Sheet metal fabrication is an essential process in manufacturing, where it’s all about precision and accuracy. At Tecvina, we understand that achieving high precision in sheet metal custom fabrication is crucial for ensuring the quality and functionality of the final product. Whether it’s for aerospace, automotive, medical, or other industries, our experts utilize advanced techniques […]

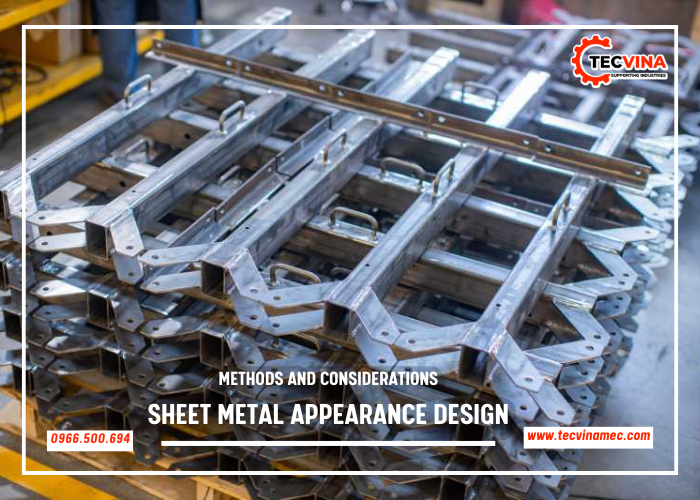

Methods and Considerations for Sheet Metal Appearance Design

The material of a product directly influences its quality. It’s safe to say that more than 80% of both large and small industrial equipment are made of metal. The primary metal materials include sheet metal, stainless steel, stretched aluminum alloys, plastic, cast aluminum, etc. Among these, sheet metal is the most widely used. Here, we […]