Lot 02, Thuy Van Industrial Zone, Thuy Van ward, Viettri city, Phutho province, Vietnam

+84966500694

Custom metal enclosures are specially-crafted covers that hold electronics, equipment, or any other items that need to be protected from the elements. They are often

Welding services are the process of joining two or more metal parts by melting and fusing them together. Welding can be done manually or by

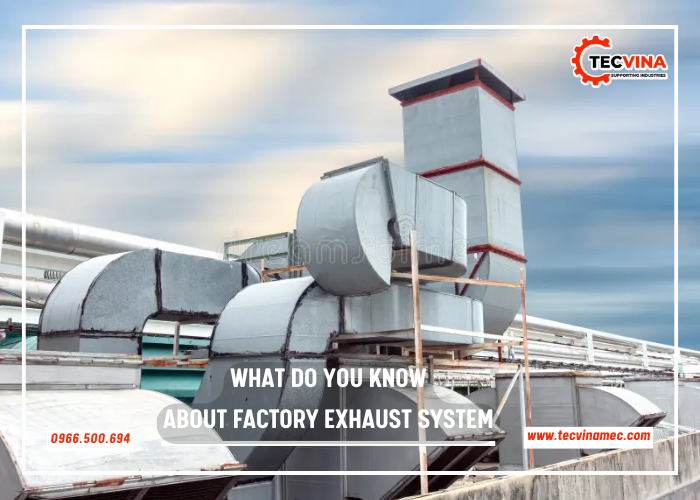

A factory exhaust system is a type of industrial ventilation system that removes heat and contaminants from specific areas of a factory and directs them

CNC drilling is a process that uses computer-controlled machines to create precise and accurate holes in various materials. CNC stands for computer numerical control, which

Electroplating is a process of applying a thin layer of metal on another metal surface by using an electric current. Electroplating can improve the appearance,

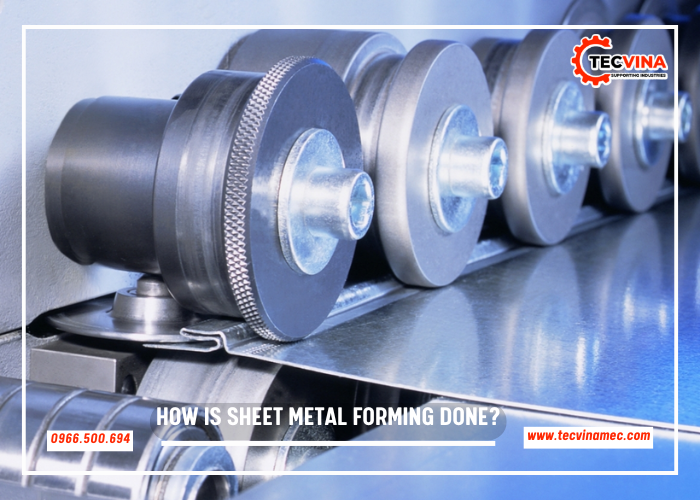

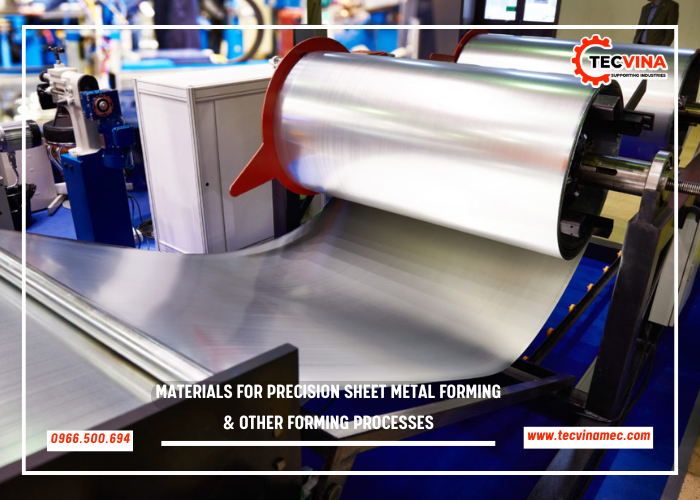

The sheet metal rolling process is a metalworking operation in which metal strips pass through a set of rollers to reduce sheet thickness and achieve

We understand the importance of safe and efficient chemical storage. The right Chemical Storage Tank is a crucial element for any facility that handles hazardous materials. It

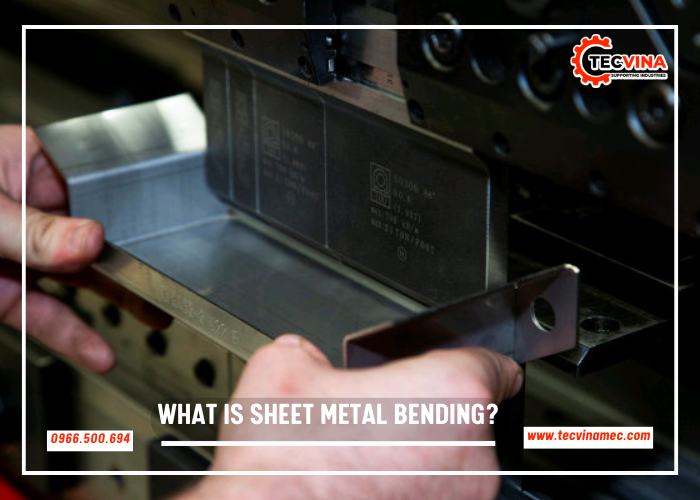

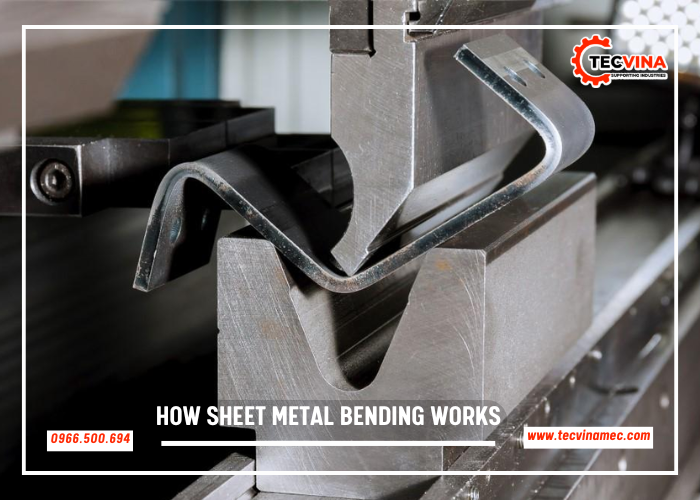

Metal bending is a process that involves the shaping of metals to a predetermined shape by applying force to it. This can be done by

Sheet metal cutting is the process of using various tools and machines to cut, shape, or bend sheet metal into different shapes and sizes. Sheet

Industrial storage tanks are essential components of many industries, including chemical manufacturing, oil and gas, water treatment, agriculture, and food processing. These tanks are designed

Metal punching is a process that uses a machine to force a tool, called a punch, through a sheet of metal to create a hole

Powder coating is a type of coating that is applied as a free-flowing, dry powder. It is electrostatically charged and then cured under heat or

MIG/MAG welding, also known as gas metal arc welding, is a frequently used welding process that allows for high welding speeds. There are two different

Robot welding is the use of mechanized programmable tools, which completely automate a welding process by both performing the weld and handling the part. It’s

TIG (Tungsten Inert Gas) welding, also known as GTAW (Gas Tungsten Arc Welding), is a process that uses a non-consumable tungsten electrode to produce the

Spot welding is a type of electric resistance welding that is used to join two or more metal sheets together. It works by applying pressure

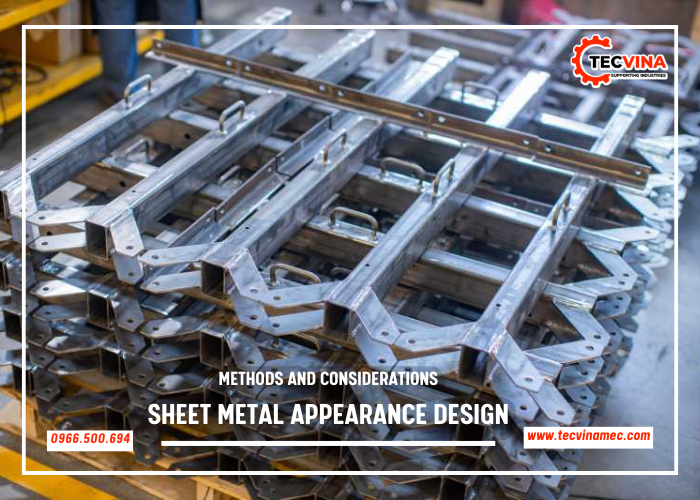

Sheet metal forming is the process of shaping metal sheets into desired shapes by bending, cutting, punching, or other processes. This process plays an important role

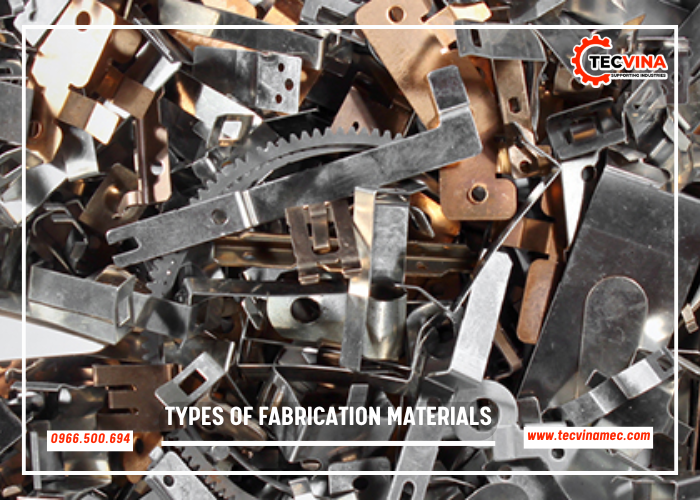

Did you know that nearly 75% of all the elements on the periodic table are classified as metals? This vast array of options provides a

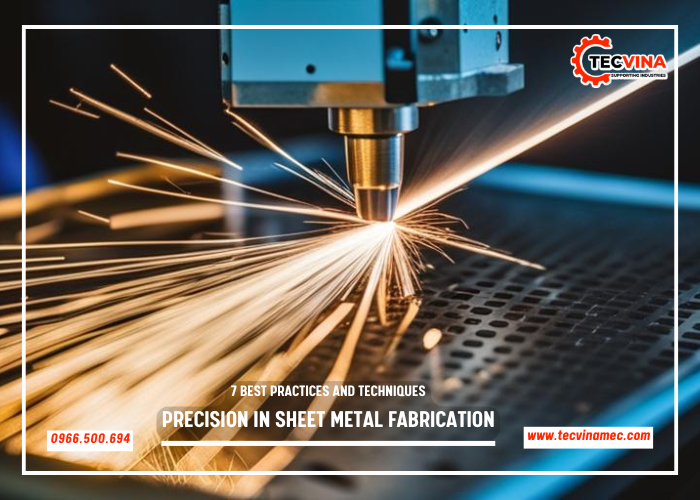

Sheet metal fabrication is an essential process in manufacturing, where it’s all about precision and accuracy. At Tecvina, we understand that achieving high precision in

The material of a product directly influences its quality. It’s safe to say that more than 80% of both large and small industrial equipment are

Precision Sheet Metal Cutting is a staple tool within metal work manufacturing, enabling the production of detailed metal parts. Precisely cutting sheet metal into the desired

Precision sheet metal forming is a manufacturing process that involves shaping metal sheets into desired geometries using high-accuracy tools and techniques. The choice of materials

There are many categories of metal forming, but all have one thing in common: the raw metal stock is being reshaped into a desired form.

At the core of the industrial world lies the intricate and expansive process of metal fabrication. It’s a craft honed over centuries, molding the infrastructure

With continuous technological advancements and evolving market demands, the metal manufacturing and stamping industries are embracing new opportunities and facing challenges in 2024. Custom metal

When it comes to storing chemicals in large quantities, bulk chemical storage tanks play a crucial role in ensuring safety and efficiency. These tanks are

Chemical storage tanks are a critical component of industrial operations across many sectors. They provide a safe and organized way to store bulk quantities of

Storage tanks are essential components widely used across various industries for the safe and efficient storage of a multitude of substances, including liquids, gasses, and

Material innovations in sheet metal forming have significantly enhanced manufacturing capabilities, enabling the production of lighter, stronger, and more versatile components for various industries. These

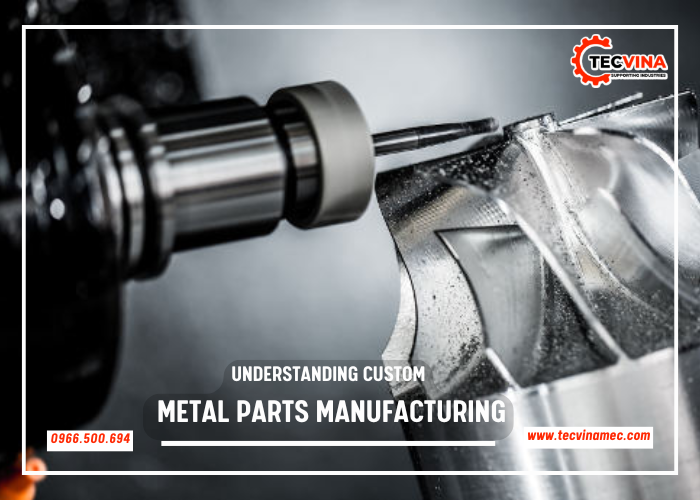

Custom metal part manufacturing involves creating tailor-made metal components that meet specific requirements in terms of design, functionality, and performance. Unlike mass production, custom manufacturing

Sheet metal forming is a versatile process used to shape flat metal sheets into desired geometries. The success of forming operations is heavily dependent on

Sheet metal is a fundamental material in industries ranging from automotive and aerospace to consumer electronics and construction. While it offers significant benefits like versatility,

1. Introduction to Sheet Metal Fabrication Sheet metal fabrication is a comprehensive manufacturing process that involves shaping, cutting, bending, and assembling metal sheets to create

Sheet metal forming is a complex and necessary part of today’s manufacturing industry, with applications ranging from the automotive sector to aerospace and beyond. The

While investigating various approaches for shaping sheet metal, it’s worth looking at a few of the most commonly employed methods. One such method is bending;

Among the many ways to change the shape of a piece of metal are bending and forming. Dating back to the Stone and Wood Ages,

Definition of Sheet Metal What is sheet metal? There is no clear definition for it. As a rule, it is understood to be a flat

What Is Sheet Metal Bending? Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It

Metal sheet fabrication is not just a technical process; it’s an intricate art form that combines scientific principles with skilled craftsmanship. It serves as the

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal is fed into a press,

When you are thinking about buying a new water storage tank, there are several things you must consider. The important considerations for most people buying

When you’re in the market for a storage tank, one of the first decisions to consider is what sort of material you require your tank

Advancements in sheet metal forming technologies and their applications The industry has been completely changed by the developments made in sheet metal forming technologies in

Metal has been hammered into sheets and used for a variety of purposes since ancient times. Water-powered rolling mills became common for use in creating

Depending on the required qualities and application requirements, both soft and hard metals are utilized in the manufacturing of sheet metal. Because of their malleability

Imagine custom metal parts as the haute couture of the manufacturing world—each piece tailored to fit its application like a glove. In this sphere, precision

Common Types Metal Used For Custom Machinery Manufacturing Steel Sheet Metal Steel is the workhorse of sheet metal fabrication. With its various alloys like carbon

Metal fabrication and machining are two commonly used processes in the manufacturing industry, but many people may not fully understand their differences. Both involve shaping

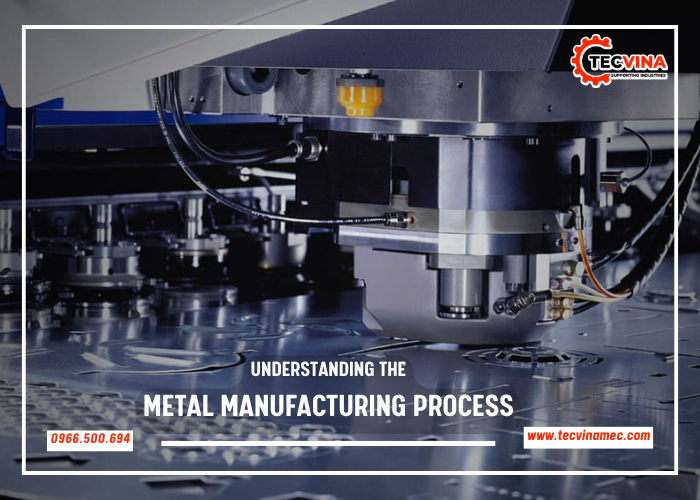

Metal manufacturing is a complicated process that follows different stages to ensure a component meets the specifications set. It starts with design and engineering where

Tecvina is a Vietnam-based trademark. Our company operates in the fields of metal processing and fabrication, industrial product assembly and production, import and export.